Ring Type Joint Weldneck

- In accordance to ASME/ANSI B16.5, MSS SP-6 & 25

- ASTM / ASME A/SA-182

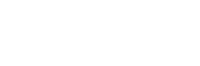

- The depth of groove is added to the minimum flange thickness

- * Raised Face “L” is equal to groove dimension “E” but is not subject to tolerance for “E”

- Sizes 1/2″ through 2-1/2″ are identical between Classes 900 and 1500

Additional Information

Use Custom Product to make a request for dimensions not shown.

Pressure-Temperature Ratings (Class 900)

| Metal Temperature F° | Pressurea (Type 304/L & 316/L) |

|---|---|

| -20 à 100 | 1800 |

| 200 | 1520 |

| 300 | 1360 |

| 400 | 1240 |

| 500 | 1145 |

| 600 | 1080 |

| 650 | 1050 |

| 700 | 1030 |

| 750 | 1010 |

| 800 | 985 |

| 850 | 965b |

| 900 | – |

| 950 | – |

| 1000 | – |

a (Pounds per Square Inch Gage)

b Class 316/L

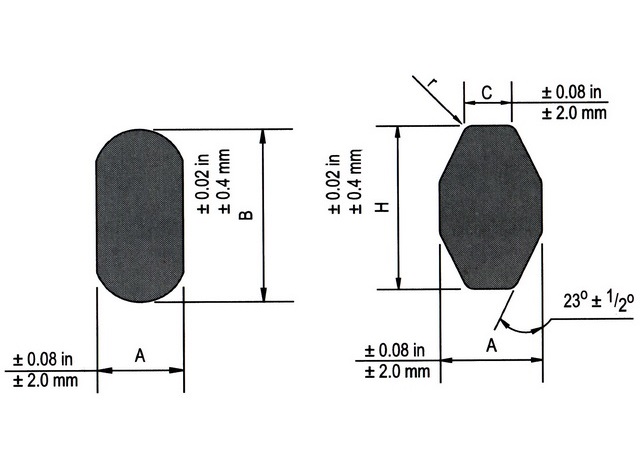

Dimensional Tolerances

| OUTSIDE DIAMETER* | When O.D. is 24” or less | ±1/16” |

| When O.D. is over 24” | ±1/8” | |

| INSIDE DIAMETER* | 10” and smaller | ±1/32” |

| 12” through 18” | ±1/16” | |

| 20” and larger | +1/8” -1/16” | |

| DIAMETER OF CONTACT FACE | 1/16” Raised Face | ±1/32” |

| 1/4” raised Face Tongue and Groove, or Male and Female | ±1/64” | |

| DIAMETER OF HUB AT POINT OF WELDING | 5” and smaller | +3/32”, -1/32” |

| 6” and larger | +5/32”, – 1/32” | |

| WELDING BEVEL STANDARDS | See drawings | |

| DIAMETER OF HUB AT BASE* | When Hub Base is 24” or less | ±1/16” |

| When Hub Base is over 24” | ±1/8” | |

| DRILLING | Bolt Circle | ±1/16” |

| Bolt hole spacing | ±1/32” | |

| ECCENTRICITY BOLT CIRCLE & FACING (with respect to Bore*) | 2 1/2” and smaller | 1/32” max |

| 3” and larger | 1/16” max | |

| LENGTH THRU HUB* | 10” and smaller | ±1/16” |

| 12” and larger | ±1/8” | |

| THICKNESS | 18” and smaller | +1/8” -0” |

| 20” and larger | +3/16” -0” | |

Back to top